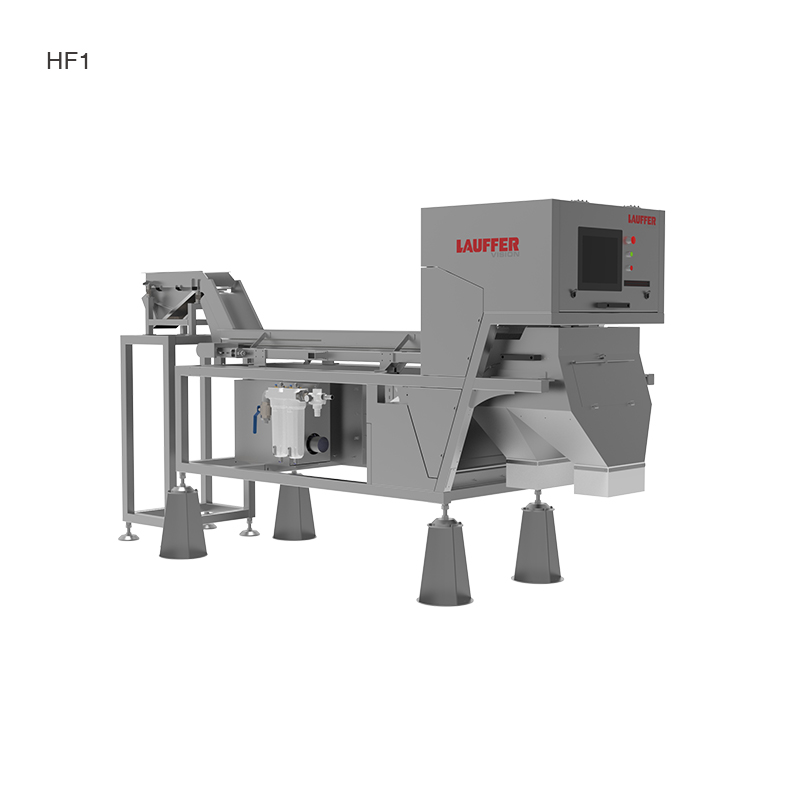

Legende HFC RGB Sorter

Designed to cost-effectively remove defective berries at the post-harvest stage of coffee cherries by high-resolution RGB cameras, ensuring consistent quality for further processing

![]() Processing Capacity Range: 3000-10000 litre per hour

Processing Capacity Range: 3000-10000 litre per hour![]()

Technical Features

● Tailored Sorting Solution for Coffee Cherries

✦ Compact single-belt sorting system with quick-install design

✦ High-capacity waterproof vibratory feeder evenly distributes coffee cherries into a single layer to minimize overlapping

✦ Reinforced food-grade stainless steel structure and sealed scanning and control boxes withstand frequent high-pressure washing and sterilization

✦ Quick belt change ensures convenient routine maintenance and cleaning, meeting higher food safety and hygiene standards

✦ Field-proven Humidity Control System integrated maintains consistent performance and minimizes downtime

✦ Modular design of belt width from 300 to 1800mm (300/600/1200/1800) provides processors more flexibility

● Cost-effective Inspection System

✦ High-Resolution RGB Camera System

✦ High-Intensity LED Illumination System

✦ Market-leading precision detection to a wide range of defects of coffee cherries by color, size, shape and texture features:

✩ Underripe cherries/green cherries

✩ Overripe cherries/black cherries

✩ Mold-infected cherries (white/gray fungal patches)

✩ Crushed/cracked cherries

✩ Shriveled/dried cherries

✩ Insect-damaged cherries

✩ Leaves/stems residues

✩ Other foreign materials

● High-Performance Ejector System

✦ Engineered for enhanced durability, optimized speed and air consumption

✦ Accurate rejection and reliable performance at high-capacity sorting

✦ Significant reduction in false rejection rate and total cost of ownership

● 15-inch Industrial Touchscreen Control Panel

✦ Intuitive HMI with multilingual support

✦ Instant switching between product profiles

✦ Comprehensive remote support system

✩ Remote Access and Monitoring

✩ Real-time Performance Dashboard

✩ Live Expert Diagnosis

✩ Interactive Troubleshooting

Best-Selling Models

Specifications

| Model |

Belt Width (mm) |

Air Nozzle |

Air Pressure (MPa) |

Air Consumption (L/min) |

Voltage |

Power (kW) |

Dimension (mm) |

Unpacked Weight (kg) |

|

Legende HFC1 |

300 | 64 | 0.6~0.8 | <1200 |

220V~50/60Hz |

3.2 | 3816×1240×1866 | 672 |

|

Legende HFC2 |

600 | 128 | 0.6~0.8 | <2400 | 220V~50/60Hz | 3.5 | 4340×1811×2144 | 882 |

|

Legende HFC4 |

1200 | 256 | 0.6~0.8 | <3600 | 220V~50/60Hz | 4.8 | 4519×2411×2144 | 1120 |

|

Legende HFC6 |

1800 | 384 |

0.6~0.8 |

<3600 |

220V~50/60Hz |

6.8 |

4502×3075×2144 |

1425 |