- Description

- Specification

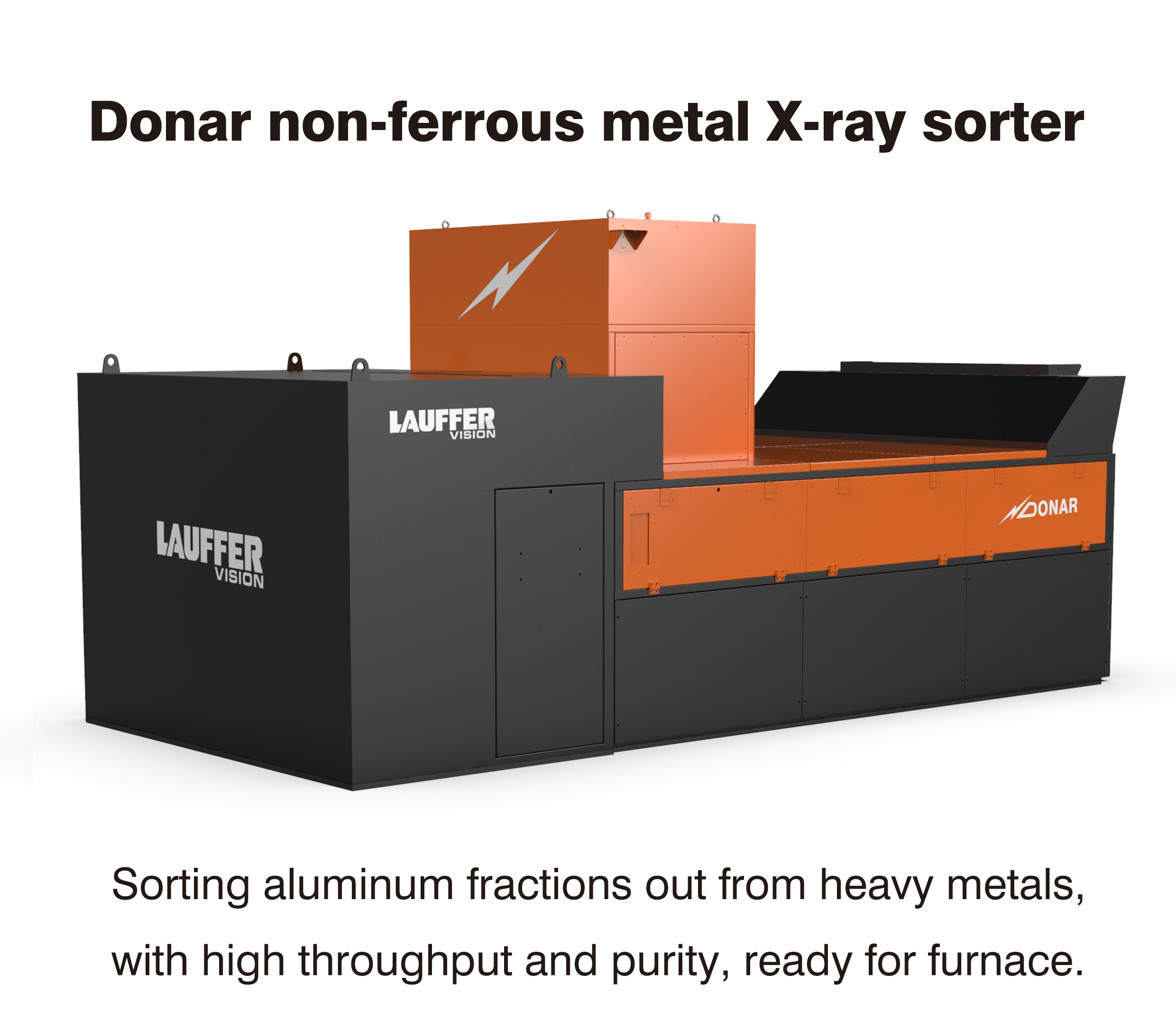

Donar X-ray sorter can be used in the recovery and purification of aluminum scraps.

Combined with Lauffer’s advanced Dual Energy X-ray Transmission (XRT) technology and superior AI Deep Learning algorithms, it can efficiently distinguish the aluminum fractions from the heavy metals (such as copper, brass, zinc, stainless steel, etc.) in the mixed non-ferrous scraps according to their atomic density to achieve the ready-to-furnace aluminum scraps.

Furthermore, the purification of wrought aluminum fraction from the cast aluminum fraction in the mixed aluminum scraps is now available to create more values and profits for the worldwide non-ferrous metal scrap processors.

Features

lAdvanced Dual Energy XRT

Accurate identification of aluminum fraction in the mixed non-ferrous metal scraps and efficient separation from the heavy metals by atomic density, shape, thickness, texture, etc.

lSuperior AI Deep Learning Algorithm

Innovative simulation of manual picking operation by teaching and training the intelligent X-ray sorter all the standards and features of identification and sorting.

lFlexible and Reliable Ejection System

High-speed and powerful ejectors designed and produced in-house ensure the flexibility and compatibility to the sorting requirements of both 10-30mm and 30-80mm.

lHiger throughput and more choices

Available in three belt widths (1200mm/1800mm/2800mm) with broad range of sorting capacity from 8-28 t/h, meeting the different requirements of various non-ferrous metal scrap processing lines.

| Model | Donar1200 |

Donar1800 |

Donar2800 |

|

Belt Width (mm) |

1200 | 1800 | 2800 |

|

Ejectors |

202 | 304 | 468 |

|

Sorting size (mm) |

10~80 |

10~80 |

10~80 |

|

Throughput (t/h) |

4~10 |

6~16 | 10~28 |

|

Air consumption (m3/min) |

15 | 20 | 25 |

|

Power (kw) |

12 | 15 | 22 |

|

Dimension (mm) |

5,675×2,436×2,349 |

5,675×2,890×2,751 |

7,780×4,142×2,594 |

|

Unpacked Weight (t) |

5.8 | 8.0 | 15.0 |